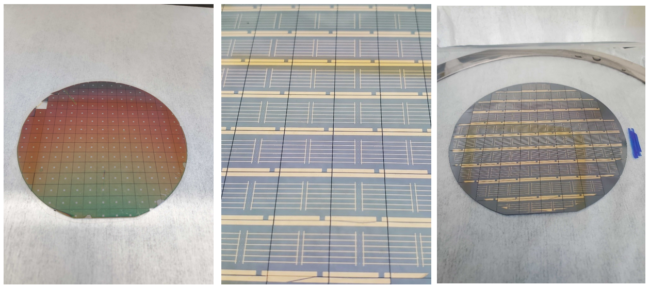

Did you know that the DISCO DAD3220 dicing saw can section blank and patterned substrates such as silicon, glass slides, sapphire, and more? You can fabricate multiple devices on one wafer and dice afterwards to save time and resources. The patterned devices can be coated with a layer of thin photoresist during the cutting for protection.

Join us on August 15, 2023 from 10:00-11:30 in 226 ESB to hear from a DISCO representative about the capabilities of the DISCO DAD3220 dicing saw in Vanderbilt University’s VINSE cleanroom, as well as other sample cutting techniques. Dicing is a standard microfabrication process to create custom-sized substrates and devices for a variety of electronic, optical, biomedical, and other applications. Silicon, sapphire, and fused quartz are commonly diced, but other materials may be available.

Learn more about the VINSE DISCO DAAD3220 Dicing Saw

Get Access to VINSE – New Vanderbilt Users

Get Access to VINSE – External Users